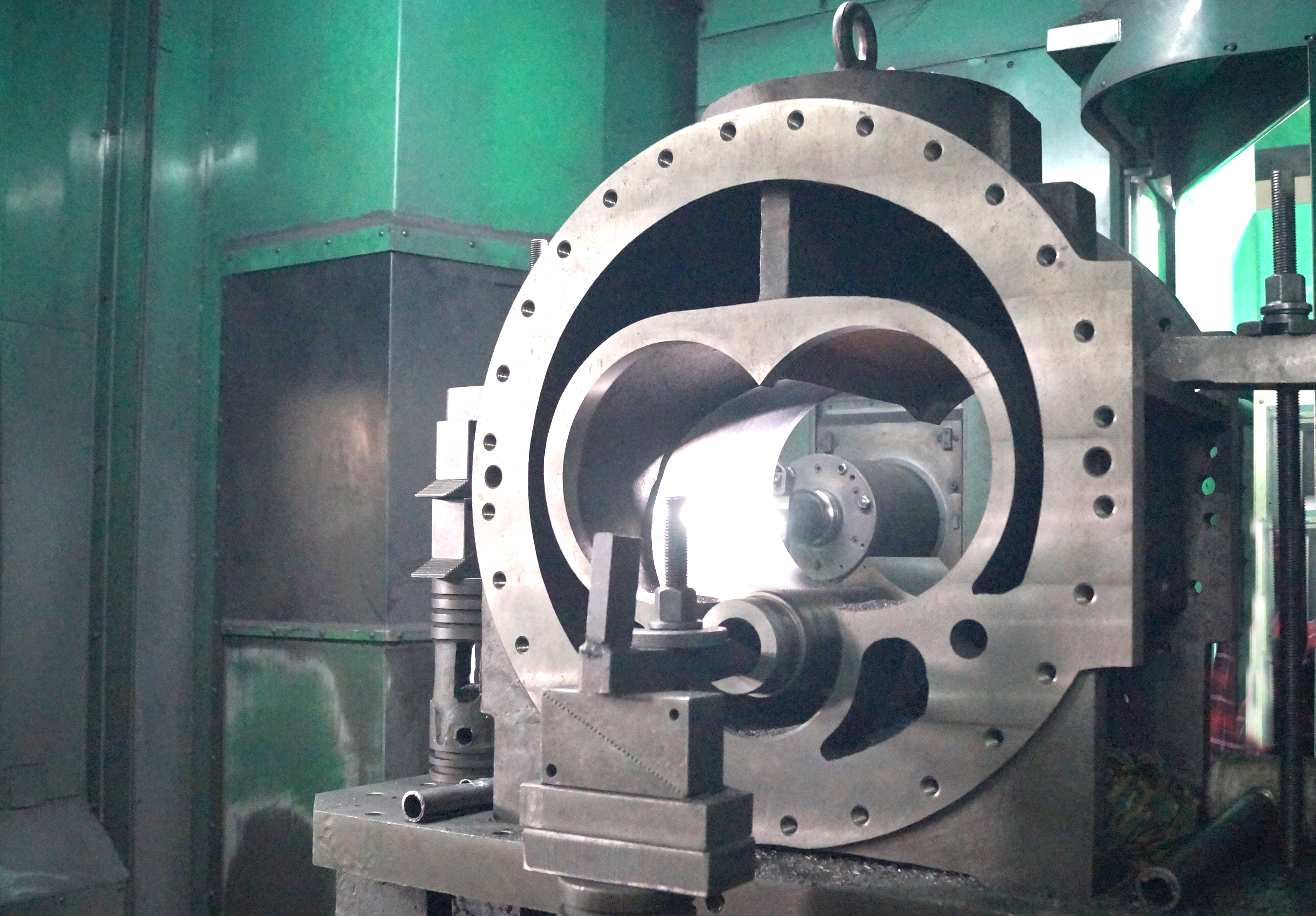

fil compressorsis is committed to manufacturing third generation highest quality compressors. The process starts with casting in our latest State-of-the-Art foundry in our Factory.

produced from casting frames does not posse concentrated stresses due to uni-body and uniformly distributed fine grain structure, resulting in precise dimensional stability during subsequent machining operations and less co-efficient of thermal expansion effects in less heat dissipation to the surrounding.

Such compressors have inherent structural integrity of uniform geometrical shapes like profiles, radius, ribs, and other complex shapes able to achieve uniform strength, good vibration damping, wear resistance and long lasting structure.

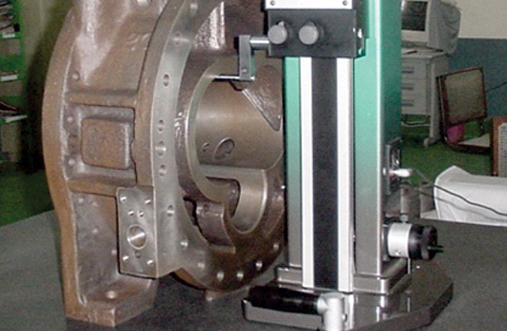

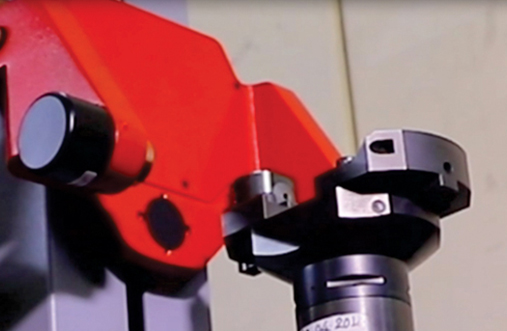

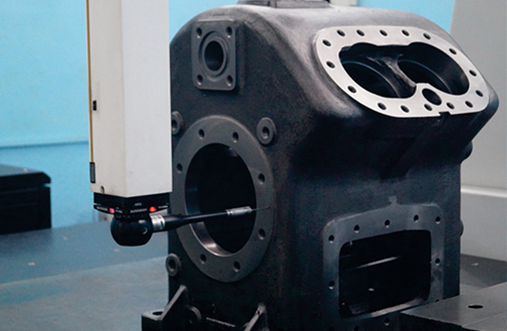

fil compressors use state of the art CNC machining system to meet the highest possible accuracy in order to produce high efficiency compressors. We use state of the art horizontal machining centres to produce casing in order to achieve accuracy.

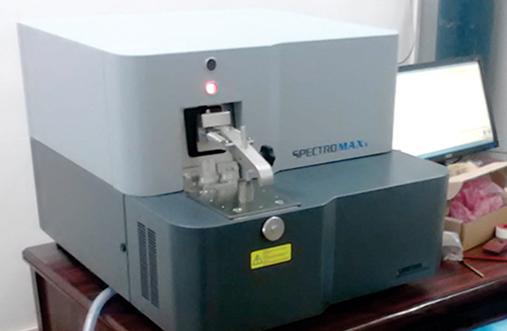

Quality assurance of all fil compressors are done at our manufacturing facility by latest machines like CMM machines, TRIMOS etc to maintain 100% accuracy.

Assembly of fil compressors and packages has been performed by technical engineers at advanced and upgraded manufacturing facility at our factory.