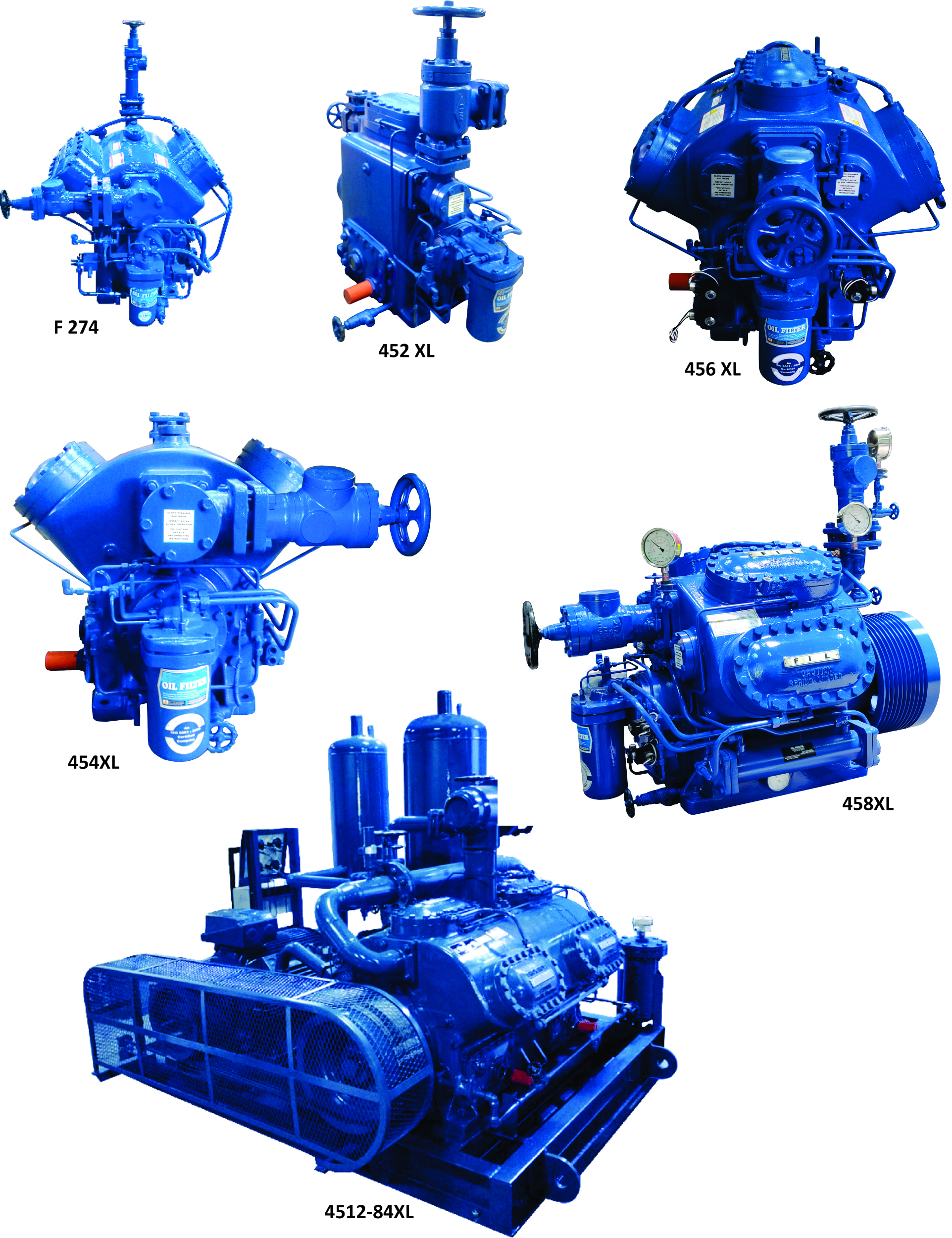

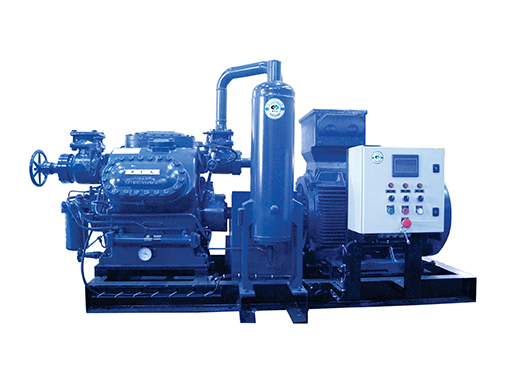

Our F-270 Series of high speed piston compressors with water ammonia-cooled cylinders. All these compressors are run at a maximum of 1450 RPM, and all are provided with built-in capacity reduction steps for economical operation on part loads. “V” belt and direct connected motor operations are also available. These high-speed compressors can operate with almost all refrigerants. It works in extreme applications with up to a 17.2 bar pressure differential. It can be belt-driven or direct-driven all the way up to 150 kW. It can run at high compression ratios all the way up to 14:1 with certain refrigerants in a single stage.

| DESCRIPTION / MODELS | 452XL | 454XL | 456XL | 458XL | 4512XL | |

| Number of Cylinders | 2 | 4 | 6 | 8 | 12 | |

| Maximum RPM | 1200 | 1200 | 1200 | 1200 | 1200 | |

| Bore & Stroke | Inch | 4 1/2 X 4 1/2 | 4 1/2 X 4 1/2 | 4 1/2 X 4 1/2 | 4 1/2 X 4 1/2 | 4 1/2 X 4 1/2 |

| mm | 114 X 114 | 114 X 114 | 114 X 114 | 114 X 114 | 114 X 114 | 114 X 114 |

| Swept Volume@ Maximum RPM | CFM (CMH) | 99.4 (169) | 199 (338) | 298 (507) | 398 (676) | 596 (1013) |

| Suction Connection - |

in. (mm) | 21/2 (69) | 3 (80) | 4(100) | 4(100) | 6(150) |

| Discharge Connection - | in. (mm) | 2 (50) | 2 / (65) | 3(80) | 3(80) | 3(80x2) |

| Unit weight Less Motor - | Lbs. (kg) | 1900 (862) | 2700 (1225) | 3100(1406) | 3400(1542) | 5580 (2565) |

| Oil Charge - | Ga (Lts) | 5(19) | 7 (27) | 7 (27) | 7 (27) | 15 (54) |

| Standard Steps of Unloading | (%) | 0 | 50/100 | 33/66/100 | 25/50/75/100 | 33/66/100 |

| Refrigerant | R-22 | NH3 | R-290(Propane) | R-134a | ||||||||||||||

| Compressor Models | Evaporative Temperature in Deg C |

Condensing Temperature | Condensing Temperature | Condensing Temperature | Condensing Temperature | |||||||||||||

| 35 Deg C | 40 Deg C | 35 Deg C | 40 Deg C | 35 Deg C | 40 Deg C | 35 Deg C | 40 Deg C | |||||||||||

| Qo KW | Pe KW | Qo KW | Pe KW | Qo KW | Pe KW | Qo KW | Pe KW | Qo KW | Pe KW | Qo KW | Pe KW | Qo KW | Pe KW | Qo KW | Pe KW | |||

| 452 XL | 5 | 165.61 | 32.26 | 153.95 | 34.94 | 192.56 | 29.89 | 184.41 | 33.58 | -- | -- | -- | -- | 100.6 | 21.2 | 93.6 | 23.0 | |

| 0 | 136.56 | 31.36 | 127.43 | 33.59 | 156.70 | 28.78 | 151.16 | 33.22 | 115.4 | 29.5 | 106.6 | 31.6 | 79.5 | 20.2 | 74.6 | 21.7 | ||

| -5 | 113.52 | 29.86 | 104.25 | 31.74 | 126.06 | 28.87 | 121.17 | 31.74 | 95.7 | 28.3 | 87.6 | 30.1 | 61.9 | 19.0 | 57.7 | 20.1 | ||

| -10 | 93.17 | 27.95 | 84.62 | 29.40 | 99.11 | 27.14 | 94.40 | 29.34 | 78.1 | 26.8 | 71.0 | 28.1 | 47.1 | 17.6 | 44.0 | 18.2 | ||

| -15 | 74.62 | 25.80 | 67.74 | 26.85 | 76.43 | 24.98 | 71.83 | 26.54 | 62.6 | 24.9 | 57.0 | 26.0 | 35.5 | 15.9 | 32.7 | 16.0 | ||

| -20 | 58.25 | 23.39 | 52.74 | 24.03 | 58.39 | 22.58 | - | - | 49.6 | 22.8 | 44.7 | 23.6 | 27.1 | 13.9 | 23.9 | 13.6 | ||

| 454 XL | 5 | 331.66 | 61.67 | 308.26 | 66.77 | 385.64 | 57.06 | 370.49 | 64.22 | - | - | - | - | 201.2 | 40.5 | 187.1 | 44.1 | |

| 0 | 273.85 | 59.94 | 255.38 | 64.23 | 313.99 | 56.91 | 302.90 | 63.47 | 231.1 | 56.4 | 213.1 | 60.5 | 159.3 | 38.7 | 148.8 | 41.5 | ||

| -5 | 227.63 | 57.14 | 208.72 | 60.63 | 252.84 | 55.24 | 242.95 | 60.69 | 191.0 | 54.2 | 175.5 | 57.4 | 123.4 | 36.4 | 115.7 | 38.5 | ||

| -10 | 186.33 | 53.41 | 169.60 | 56.21 | 198.80 | 51.90 | 189.01 | 56.05 | 155.8 | 51.2 | 142.4 | 53.8 | 94.3 | 33.6 | 87.9 | 34.8 | ||

| -15 | 149.24 | 49.29 | 135.84 | 51.30 | 153.23 | 47.72 | 143.66 | 50.72 | 125.2 | 47.7 | 113.6 | 49.6 | 71.0 | 30.3 | 65.4 | 30.6 | ||

| -20 | 116.86 | 44.67 | 105.48 | 45.88 | 116.86 | 43.12 | - | - | 98.8 | 43.6 | 89.0 | 45.0 | 53.8 | 26.6 | 47.8 | 25.9 | ||

| 456 XL | 5 | 497.28 | 90.60 | 462.21 | 98.13 | 578.20 | 83.91 | 554.00 | 94.41 | - | - | - | - | 301.8 | 59.5 | 281.0 | 64.8 | |

| 0 | 410.41 | 88.14 | 382.81 | 94.44 | 470.69 | 83.67 | 454.10 | 93.31 | 46.4 | 83.0 | 319.7 | 88.9 | 238.8 | 56.9 | 223.3 | 61.1 | ||

| -5 | 341.15 | 84.00 | 312.97 | 89.14 | 378.90 | 81.24 | 364.14 | 89.22 | 286.6 | 79.6 | 263.1 | 84.4 | 185.3 | 53.5 | 173.4 | 56.5 | ||

| -10 | 279.50 | 78.49 | 254.22 | 82.65 | 297.90 | 76.30 | 283.45 | 82.38 | 233.9 | 75.2 | 213.5 | 79.0 | 141.4 | 49.4 | 131.9 | 51.2 | ||

| -15 | 223.86 | 72.48 | 203.58 | 75.39 | 229.66 | 70.17 | 215.49 | 74.55 | 187.8 | 70.0 | 170.6 | 72.9 | 106.6 | 44.7 | 97.8 | 45.0 | ||

| -20 | 175.10 | 65.65 | 158.22 | 97.43 | 175.25 | 63.35 | - | - | 148.4 | 64.1 | 133.6 | 66.2 | 80.9 | 39.1 | 72.1 | 38.0 | ||

| 458 XL | 5 | 661.44 | 120.79 | 614.71 | 130.86 | 769.03 | 111.81 | 736.90 | 125.85 | - | - | - | - | 402.3 | 79.3 | 374.6 | 86.4 | |

| 0 | 546.11 | 117.46 | 507.71 | 125.90 | 626.16 | 111.54 | 604.03 | 124.41 | 461.8 | 110.7 | 426.6 | 118.6 | 318.6 | 75.8 | 297.5 | 81.4 | ||

| -5 | 453.95 | 111.99 | 416.14 | 118.82 | 504.23 | 108.28 | 484.49 | 118.98 | 381.9 | 106.2 | 350.6 | 112.6 | 247.2 | 71.4 | 231.4 | 75.4 | ||

| -10 | 371.58 | 104.67 | 338.18 | 110.20 | 396.50 | 101.73 | 376.98 | 109.86 | 311.6 | 100.3 | 284.5 | 105.4 | 188.2 | 65.9 | 175.9 | 68.2 | ||

| -15 | 297.76 | 96.64 | 270.95 | 100.59 | 305.73 | 93.51 | 286.62 | 99.40 | 250.4 | 93.4 | 227.2 | 97.2 | 141.7 | 59.6 | 130.5 | 60.0 | ||

| -20 | 232.99 | 87.53 | 210.24 | 89.93 | 232.99 | 84.50 | - | - | 197.7 | 85.5 | 178.0 | 88.3 | 108.0 | 52.2 | 96.0 | 50.8 | ||

| 4512 XL | 5 | 1122.9 | 167.9 | 1086.8 | 184.7 | - | - | 866.9 | 176.2 | - | - | - | - | - | - | 581.7 | 141.4 | |

| 0 | 914.2 | 167.4 | 890.1 | 183.1 | 777.2 | 164.9 | 731.2 | 178.5 | 693.2 | 165.4 | 640.4 | 177.3 | 500.4 | 133.6 | 464.9 | 137.9 | ||

| -5 | 736.1 | 162.5 | 713.7 | 175.7 | 650.6 | 160.3 | 609.1 | 171.3 | 573.6 | 158.8 | 527.2 | 168.4 | 398.5 | 125.6 | 368.2 | 127.5 | ||

| -10 | 578.7 | 152.7 | 557.1 | 162.8 | 534.9 | 152.6 | 497.6 | 161.3 | 468.4 | 150.1 | 428.0 | 157.7 | 312.6 | 114.0 | 287.0 | 114.1 | ||

| -15 | 446.3 | 140.4 | 424.1 | 147.6 | 429.4 | 142.4 | 396.3 | 148.9 | 376.7 | 139.7 | 342.2 | 145.5 | 239.8 | 100.5 | 218.0 | 99.4 | ||

| -20 | 340.4 | 126.8 | 319.5 | 131.7 | 335.2 | 130.3 | 305.6 | 134.8 | 297.5 | 128.1 | 268.3 | 132.3 | 176.2 | 86.6 | 157.9 | 84.9 | ||